| Ketema | Sondex | Alfa Laval | Tranter |

Schmidt-Bretten Gasketed Plate Heat Exchangers |

|||

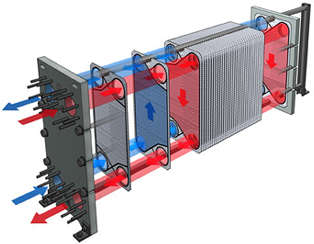

| Plate Heat Exchangers utilize corrugated plates stacked between a fixed and a movable pressure plate. The corrugation patterns alternate for maximum operating pressures. As virtually all of the material is used for heat transfer, Plate Heat Exchangers can have large amounts of effective heat transfer surface in a small footprint. It is not uncommon that a Plate Heat Exchanger will have the same thermal capacity as a Shell & Tube five times larger.

The unique corrugation pattern pressed onto each Schmidt-Bretten thermal plate produces the highest overall heat transfer rate by assuring highly turbulent flow and excellent fluid distribution across the entire surface. With high heat transfer rates and true counter current flow, API Plate Heat Exchangers economically handle close temperature approach requirements. |

|||

|

|||

| Frame: | Painted Carbon Steel, or 304 Stainless Steel | ||

| Plates: | Stainless: 304 and 304L stainless; 316 and 316L stainless

Exotics: Titanium, Titanium-Palladium, SMO-254, Incoloy 825, Nickel, Hastelloy, Monel, Inconel, Tantalum |

||

| Gaskets: | Nitrile, EPDM, Viton, Compressed Fiber, Glued or Clip-on designs | ||

| Connections: | FPT, MPT, Studded, Flanged, Tri-Clamp, others | ||

| Capacities: | 0.5 GPM to 8800 GPM | ||

| Codes: | ASME | ||

|

|||

|

|||

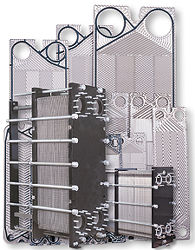

| API Heat Transfer’s line of Schmidt-Bretten Plate Heat Exchangers incorporate superior design features to ensure long term customer satisfaction. | |||

|

|||

| Plate and Frame Exchangers are available in a variety of plate sizes for industrial, HVAC or sanitary applications. | |||

| Typical applications include: | |||

|

|

||

| For complete information on this product visit our Literature section for a free download of the Schmidt-Bretten Plate Heat Exchangers brochure. | |||

| Click here to view the Schmidt-Bretten Plate Heat Exchangers Users Manual Download an animation of Gasketed PHE disassembly (9.6 MB) |

|||