| Ketema | Sondex | Alfa Laval | Tranter |

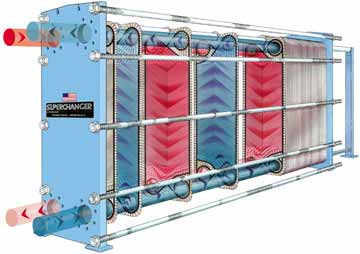

| Plate and frame heat exchangers are the most practical and efficient design of a heat exchanger in the market place. The unit consists of a series of gasketed, embossed metal plates bolted together between end frames to form channels through which hot and cold media flow. | |

| The Superchanger’s plate and frame design offers many advantages over its shell and tube counterpart in that it is expandable, cleanable, compact and efficient. The “U” values are up to five times greater than other exchangers. | |

|

Key Benefits

|