| Alfa Laval | Schmidt Bretten | WTT |

Schmidt-Bretten Brazed Plate Heat Exchangers |

|||

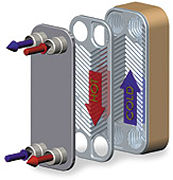

| Brazed Plate Heat Exchangers represent the most compact, rugged and cost-effective means of transferring heat in many industrial and refrigerant applications. Built from 316 stainless steel with copper brazing materials, they provide exceptional corrosion resistance. The SB-Series features corrugated plates that produce highly turbulent flow in a true counter-current direction. This results in high efficiency and a very compact heat exchanger design. Due to the smaller size and reduced material content, they can be the most economical heat transfer choice. | |||

|

|||

| Plates: |

316 Stainless Steel |

||

| Braze Material: |

Copper |

||

| Connections: |

3/4″ to 4″ NPT, Soldering

SAE Type, Flanged |

||

| Capacities: |

20 GPM to 385 GPM

1/2 Ton to 100 Ton |

||

| Approvals: |

UL Stamp

ASME UM stamp is available by special order. |

||

| API Heat Transfer Brazed Plate Heat Exchangers are available for process and refrigeration applications. Made from stainless-steel plates and copper or nickel brazing materials, they are suitable for a wide variety of heat exchanger applications. | |||

| Brazed Plate models are available with dual circuits as shown here. | |||

| Typical applications include: | |||

|

|||

| For complete information on this product visit our Literature section for a free download of the Schmidt-Bretten Brazed Plate Heat Exchangers brochure. | |||

| Click here to view the Schmidt-Bretten Brazed Plate Heat Exchangers Users Manual | |||

| To contact an API Heat Transfer Sales Engineer directly, click here | |||