| Of all the numerous mechanical processes regularly occurring in industry today, perhaps none is more prevalent than the compression of air and other gases. Whether the compressed gas is used as a motive power source to drive machine tools or a feed stock in processes like air separation or fertilizer manufacturing, gas compression is the backbone of many critical processes.

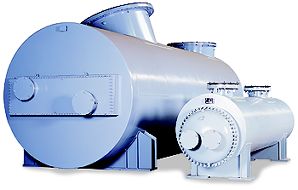

Most industrial compressors operating today are a multistage design. Increasing the number of compressor stages optimizes the cost of compressing gases; thus it is not unusual for industrial compressors to have three or more stages of compression. A prerequisite for a multi stage compressor is to cool the gas between compression stages. Thus the role of the compressor intercooler is to provide cooler, dryer, denser air to the next stage of compression. In addition to interstage coolers, the compressor’s final discharge is usually routed through an aftercooler, which also provides cooler and dryer gas to the end use point. API Heat Transfer’s Basco Type “ES” (Extended Surface) plate fin heat exchanger is the industry leader for intercooler and aftercooler performance. Its unique, patented, compact plate fin design gives the user distinct advantages for centrifugal and axial compressor applications. First and foremost, the Type “ES” heat exchanger allows practically unlimited nozzle locations to minimize the compressor gas piping. The results are lower pressure drops in the interstage piping and lower cost pipe runs. Second is the very low gas side pressure drop due to the inherent design of the Type “ES”. This low-pressure drop translates to continued power savings for the plant operator.

|

||||||||||||||||||

| The Basco Type ES is an inherently vibration free design. There are no concerns about the “ES” cooler generating compressor-damaging harmonic frequencies due to tube vibration. Our plate fin design also eliminates the need for an external moisture separator. This further simplifies piping while reducing the total system pressure drop. Should tube cleaning be required, the Basco Type “ES” permits easy access to the tube ends without removing the intercooler bundle. | ||||||||||||||||||

|

||||||||||||||||||

| Finally, API’s Basco Type “ES” cooler uses less water than other intercooler designs. Our design permits a temperature cross that results in lower cooling water consumption, less costly piping systems and lower pumping costs. | ||||||||||||||||||

|

The Basco Type “ES” cooler is available for gas flows up to 220,000 SCFM and operating pressures up to 600 PSIG. They can be fabricated from any weldable material and a wide array of tube materials to meet your specifications. |

||||||||||||||||||

|

||||||||||||||||||

Water Chilling Supply > Type “ES” Intercoolers